ProSec

Simulation of brazed plate fin heat exchangers

ProSec is a software dedicated to the simulation of multi-fluids plate fin heat exchangers, and in particular brazed aluminium exchangers. It is capable of modelling the full complexity of this type of equipment.

Main features

A precise description of complex industrial heat exchangers.

Simulation in a complete process in ProSimPlus or in any CAPE-OPEN compatible simulator.

An intuitive interface for describing the complexity of the exchangers and analyzing the results.

Thermophysical properties provided by the user or generated automatically in ProSimPlus or via CAPE-OPEN for other simulators.

A reference software chosen by the leaders in the field.

ProSec allows the user to accurately represent brazed plate-fins exchangers and to exploit simulation results for design, revamping as well as for existing plants process analysis.

ProSec allows the user to accurately represent brazed plate-fins exchangers and to exploit simulation results for design, revamping as well as for existing plants process analysis.

This heat exchanger technology, derived from the aeronautic industry, allows a large exchange surface with respect to volume and enables to reach small temperature pinch while ensuring simultaneous heat exchanges between several fluids. Thanks to its small size, this equipment was initially used in air separation and oxygen production applications. Today, it is operated in a wide variety of gas purification or liquefaction processes, including air constituents, natural gas or other hydrocarbons. They are used in single phase (liquid or vapour) but also in double phase (condensation and / or evaporation).

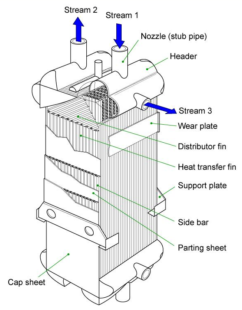

A brazed plate-fin heat exchanger consists of stacked corrugated sheets (fins) of various geometries, separated from each other by flat plates and sealed along the edge with bars. Fluids circulate in the adjacent flows that are created. According to the width, length of the sheets, the type of fin (straight, perforated, serrated, etc.), the number of stacked sheet, the fluid fitting sequence between flows, etc. numerous designs are feasible. The thermal engineer can benefit from this flexibility to design an exchanger that will satisfy the targeted heat transfers while respecting pressure drop constraints.

ProSec was designed to help him in this task, allowing him to easily check the impact of a design change on the temperature or the pressure of the “cold box” outflows. ProSec is the result of many years of research conducted with the Laboratoire de Génie Chimique (LGC) (www.lgc.cnrs.fr) and Fives Cryogénie (http://www.fivesgroup.com), a leading manufacturer of this type of exchanger. This collaborative development has allowed rigorous validation of the correlations used for the calculation of exchange coefficient or of pressure drops and, most of all, has enable the representation of the full complexity of this type of equipment.

Other products are available for the simulation of this type of exchanger but they find their limits at three levels:

They assume that the wall temperature is constant (this assumption is held in the ProSimPlus brazed plate fins exchanger module),

They are not able to take into account the complexity of fluids and flows sequences,

Numerical methods used do not allow the convergence as soon as the complexity of the industrial exchanger increases.

“Advanced simulation tools are required to design industrial heat-exchangers. The parameters of the heat-exchangers need to be mastered with a high level of accuracy in order to be able to evaluate their integration in the global production cycle. The product ProSim-Simulis enables our group to control the critical thermodynamic aspects of the exchangers. We make use of the product ProSimPlus-ProSEC to validate all the design parameters of our heat-exchangers.”

Mr. Florian PICARD

R&D engineer

Fives Cryo, France

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

Complete reliable results

ProSec calculates the thermal performances and the pressure drops of a unit operation, or a battery of unit operations in parallel. From a description of the exchanger (topology of the fluids, definition of the fins, lengths of exchange of the various paths …), thermodynamic and transport properties of the fluids, the software calculates:

- outputs global characteristics (temperature, physical state, pressure)

- fluids temperatures profiles in each paths according to the length

- parting sheets temperatures profiles according to the length

- heat convection, which is carried out for monophasic or diphasic fluids (boiling and condensation)

the effects of misdistribution of the streams in the fitting sequences

Accurate and realistic representation

Robust calculation methods ensure good convergence and enable the user to design the heat exchanger in details while limiting the number of modelization hypothesis. In particular, the following elements are taken into account:

- the fitting sequence of the fluids in the passages, and the behavior of each passage individually

up to 20 fluids (pure substances or mixtures) in co-current or counter-current flow - exchange fins characteristics, available from the database, manufacturers or provided by the user

feeds and intermediate side streams - redistributions with or without side streams in the intermediate distributor

- stream total flowrate splitting ratio in each passage

Specifically adapted algorithms

Given the complexity of the equipment, the mathematical representation model includes a great number of equations of various forms. Specific resolution strategies and custom numerical methods have been implemented to ensure simulation convergence without tedious tests.

These unique developments on numerical methods were conducted mainly by the LGC within the framework of several PhD theses among which:

- Hervé PINGAUD: Simulation statique et simulation dynamique des échangeurs à plaques brasées.

(Static simulation and dynamic simulation of brazed plate-fins exchangers)

PhD, Institut National Polytechnique de Toulouse -1988. - David AVEROUS: Modélisation et simulation des échangeurs de chaleur multifluides à plaques brassées en configuration complexes.

(Modelling and simulation of multi-fluids brazed plate-fins heat exchangers in complex configurations)

PhD, Institut National Polytechnique de Toulouse – 2000. - Khaled HAMMADI: Analyse expérimentale modélisation et simulation des échangeurs de chaleur à plaques brasées utilisés comme condenseurs à reflux.

(Experimental analysis, modelling and simulation of brazed plate-fin heat exchangers used as reflux condensers)

PhD, Institut National Polytechnique de Toulouse – 2001

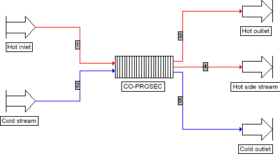

- ProSec-flowsheet

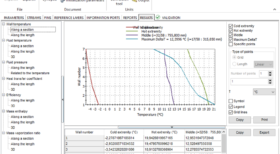

- Parameters

- generated report – Graphical results

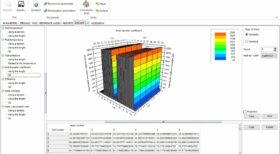

- ProSec -3D Results

- Simualtion flowsheet

Application examples

- Thermal efficiency and pressure drop calculations of an exchanger in a air distillation unit

- Thermal analysis of a network of exchangers in parallel in a natural gas liquefaction process

- Mechanical constraint anticipation through a dynamic simulation of a heat exchanger

View more resources (application examples, tutorials…) about ProSec