ProSimPlus Energy

Simulation and optimization for energy efficiency of steady-state processes

In many industries (food & beverage, chemicals, pulp & paper…), the improvement of energy efficiency to control energy consumption represents a major challenge both environmentally and economically. While general engineering simulation software can be expensive and complex to implement, and other tools provide only a partial and simplistic analysis of the problem, ProSimPlus Energy is tailored for the energy managers, energy auditors, eco-efficient facilities designers, and all other engineers responsible to solve these important challenges.

Main features

Specific unit operations dedicated to energy efficiency improvement (heat pumps, ORC…), utilities production (boilers, fuel turbines…) and waste recovery (combustion, methanization…)

Energy audit tool for an entire process using the pinch analysis technology to maximize energy savings

Exergy analysis capability

Process economic evaluation (CAPEX and OPEX)

Easy-to-use and open software to expand capabilities

ProSimPlus Energy is a must-have software to improve process energy efficiency.

- model a process, quantify its energy performance and then optimize it,

- easily perform pinch analysis in order to compare actual heating and cooling utilities against targets to eliminate on unnecessary energy use,

- combine the energy analysis of a process and the production of associated utilities all without leaving the process simulator,

- analyze any kind of thermodynamic cycle and its interaction with the process.

Reducing operating costs and optimizing capital investment

Users will benefit from ProSimPlus Energy to obtain CAPEX and OPEX estimates for comparing and screening multiple process schemes and alternative technologies and designs.

The software will give a clear vision of each operating cost involved in the process: raw materials cost, utilities cost (hot, cold and electricity) and waste effluents cost. The results will then be used as critical data for engineers to take decisions on how to improve energy efficiency while reducing costs.

Capital expenditure primarily comprises additional costs for using more efficient machines and measures to increase process efficiency. Because ProSimPlus Energy simulates accurately with high fidelity, it serves as a tool to test cost-effective process upgrades or evaluate new technologies that improve the energy efficiency, helping process industries to address environmental and market pressures, while minimizing R&D investments.

A comprehensive thermodynamic package to support the full range of process industries

ProSimPlus Energy includes the unrivalled thermophysical properties and phase equilibria calculation server Simulis® Thermodynamics, which generates highly accurate properties (thermodynamic, transport, compressibility…) as well as fluid phase equilibria, even for the most complex mixtures. (See Simulis® Thermodynamics documentation).

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

A full set of unit operations dedicated to energy efficiency

In addition to standard unit operations (heat exchangers, pumps…) the library of ProSimPlus Energy includes specific unit operations for energy management to help users quickly find the best way to improve the energy efficiency of the full process.

• Energy efficiency: heat pump, refrigeration cycle, Organic Rankine Cycle (ORC), two-stage heat pump, heat pump with partial injection;

• Utilities production: fuel turbine, fuel engine, boiler;

• Waste recovery: gas combustion, methanization reactor;

Benefits:

- easily represent the utilities path inside the process and test alternative scenarios by modifying equipment characteristics.

- simultaneously model utilities production and their use in the process.

- implement energy optimization decisions without being subject matter experts.

- improve waste recovery by rapidly testing process alternatives.

Energy audit tool of an entire process using the pinch analysis technology

The pinch analysis module is used to carry out energy integration calculations and analysis using the pinch technology. Such energy integration helps designers to compare actual heating and cooling utilities against targets based on pinch technology, identify design improvements and forecast utility expenditures. From the enthalpy curves of each stream, the hot and cold composite curves are plotted. According to the pinch temperature selected for the whole process (minimum temperature difference between the hot and cold streams), the minimum requirements in utilities (hot and cold) are calculated.

The process unit operations involved in the pinch analysis are those where heating or cooling occurs (heat exchangers, column boilers and condensers, flashes, reactors…). They are automatically detected and the required information transferred to the pinch analysis module.

Benefits:

- provide designers with the necessary data to achieve financial savings by better process heat integration (maximizing process-to-process heat recovery and reducing the external utility loads).

- optimize the heat exchanger network during the design or revamp of the process.

Exergy Analysis

Exergy has been shown to be a very useful concept to quantify the fraction of energy that can be practically recovered. Quantifying not only the energy available in a process but also its “quality” in terms of recovery, exergy is a very powerful concept when dealing with energy efficiency. However, up to now the exergy concept was poorly used by process engineers, partly because it was not readily available in process simulation software. To make exergy analysis more accessible and to demonstrate its value for the analysis of the energy efficiency of a process and its utility system, a fully-automated exergy analysis tool has been developed and is now available into ProSimPlus Energy.

Exergies are calculated as an extensive property of each stream. Energy and exergy balances are thus performed not only for the whole plant but also for each equipment in order to evaluate and point out the irreversibilities and thermodynamic inefficiencies.

Benefits:

- this unique function allows users to identify a more efficient process taking into account all the constraints. In terms of results, the module shows the exergy balances of each unit operation, making use of tables and charts, such as Grassmann diagrams.

A software very quickly adopted by users

No software, regardless of its capabilities, will bring payback if it is not used. ProSimPlus Energy is very intuitive and do not require long and expensive training to become fully operational. The Windows® based graphical environment provides many features to easily build process flow diagrams: drag and drop, copy and paste of unit operations, colors, sizing, sub-flowsheets, tree view, image and text insertions, zooming , different views of the same process… Quick analysis and understanding of simulation results is supported by many “one-click” functions such as plotting charts, profiles of heat exchangers, retrieving global material balances…

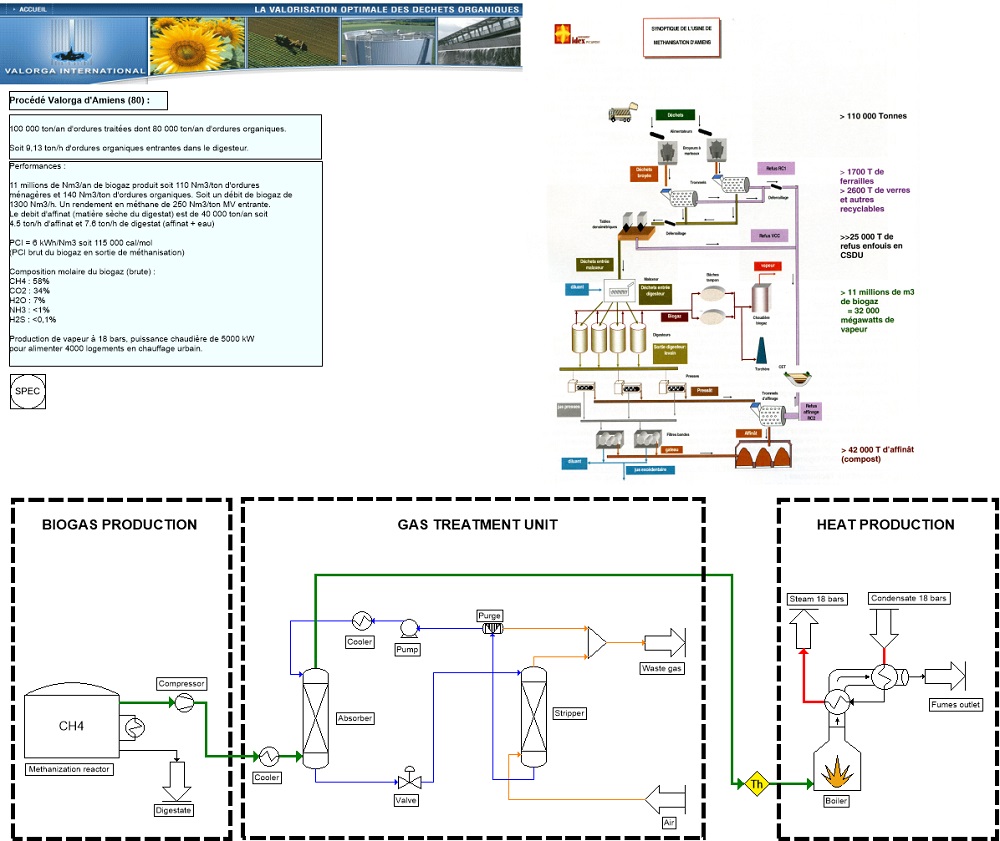

- Methanization process modeling

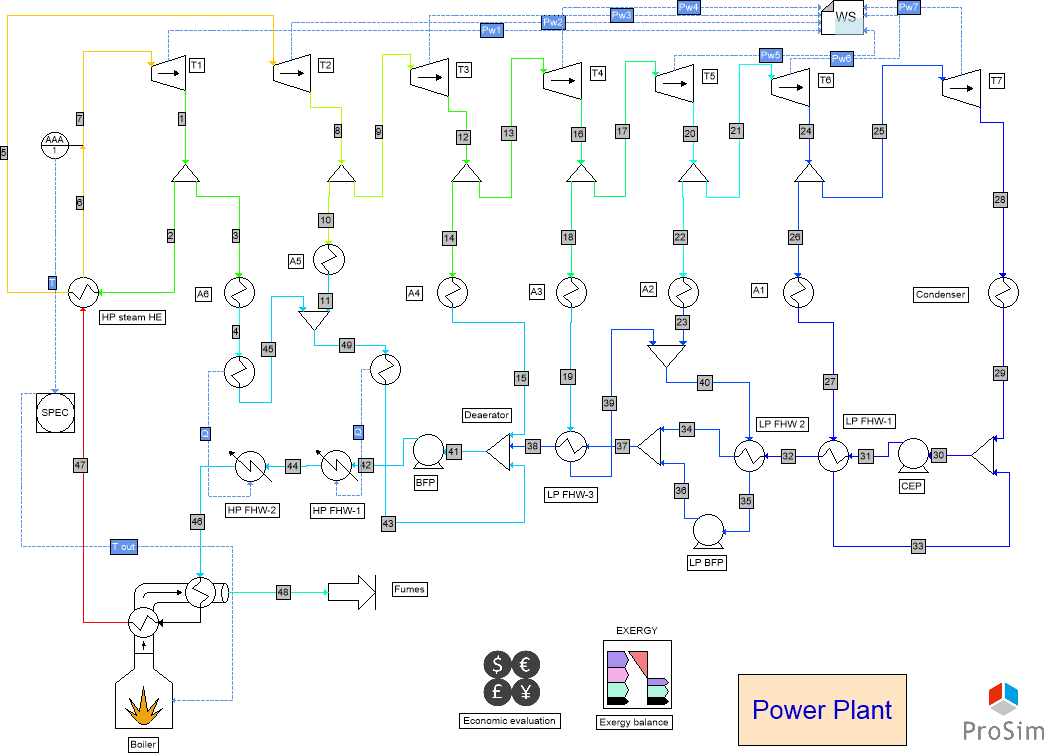

- power plant process simulation

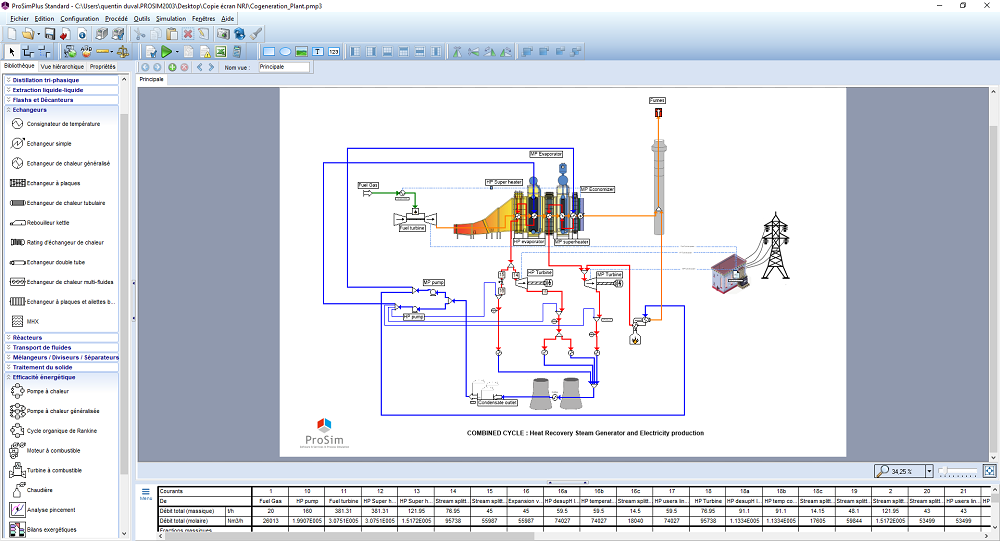

- Cogeneration Plant