Simulis Pinch

Water and energy savings in industrial processes

Dedicated to process integration, Simulis Pinch allows any engineer to easily apply the pinch technology to find the best possible use of energy and water in industrial processes. Simulis Pinch makes it possible to find an optimum network (heat exchanger and/or water) that achieves the right compromise between investments and operating cost, to reach the target of energy or water consumption reduction.

In most industrial processes, reducing energy and water consumption is a major economic and environmental challenge. Using the pinch method, to recover waste heat by strategically exchanging heat between hot and cold streams within the process, is an excellent choice to reduce energy consumption. Likewise, the reuse of water, with or without regeneration, is a way of reducing water consumption and waste in a process.

When the number of exchanges is small, finding the optimum configuration manually is easy. But when many configurations are possible, an appropriate methodology and a specific tool become necessary.

Simulis Pinch is the ideal tool to implement pinch technology to achieve the most effective use of energy and water in industrial processes. This software quantifies the potential savings of energy and water in a plant and proposes a new and better integrated process configuration to meet the water-energy nexus.

Main features

All of the features required for an advanced energy and/or water audit in a unique tool.

Automatic and fast synthesis of an efficient network of heat and/or water exchangers.

Great configuration flexibility for process design and revamping.

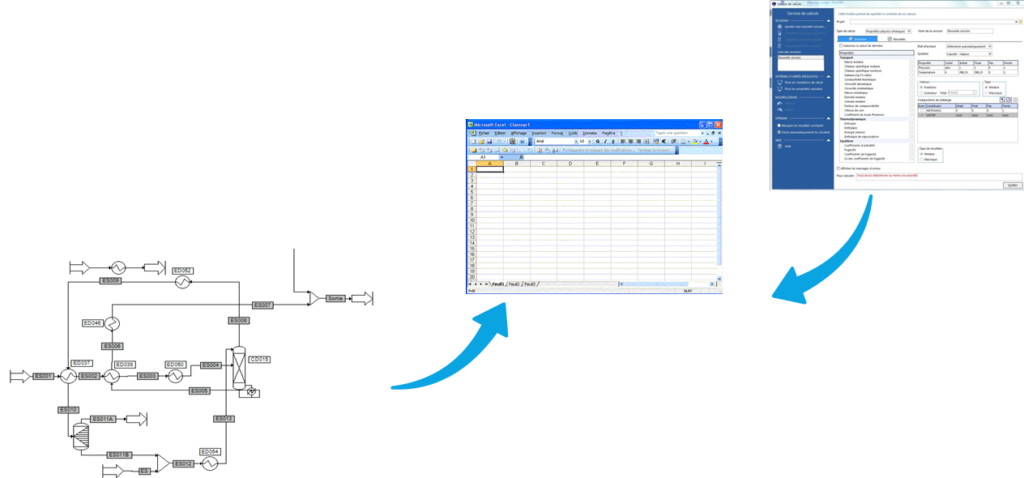

Microsoft® Excel Add-in with complete results processing and analysis that is simple to use.

Available as a standalone solution or integrated within a process simulation software.

ENERGY AND WATER EFFICIENCY – ACHIEVE SIGNIFICANT ENERGY AND WATER SAVINGS WITH SIMULIS PINCH

All the features required for an energy and water audit in a unique tool

Simulis Pinch is made up of two modules which allow the integration of processes in Microsoft® Excel: Simulis Pinch Energy and Simulis Pinch Water.

Simulis Pinch Energy allows to easily apply the pinch technology to find the best possible energy exchanges between streams to be heated and streams to be cooled. The objective of this tool is to propose an optimal network of heat exchangers to reduce the energy consumption of a process.

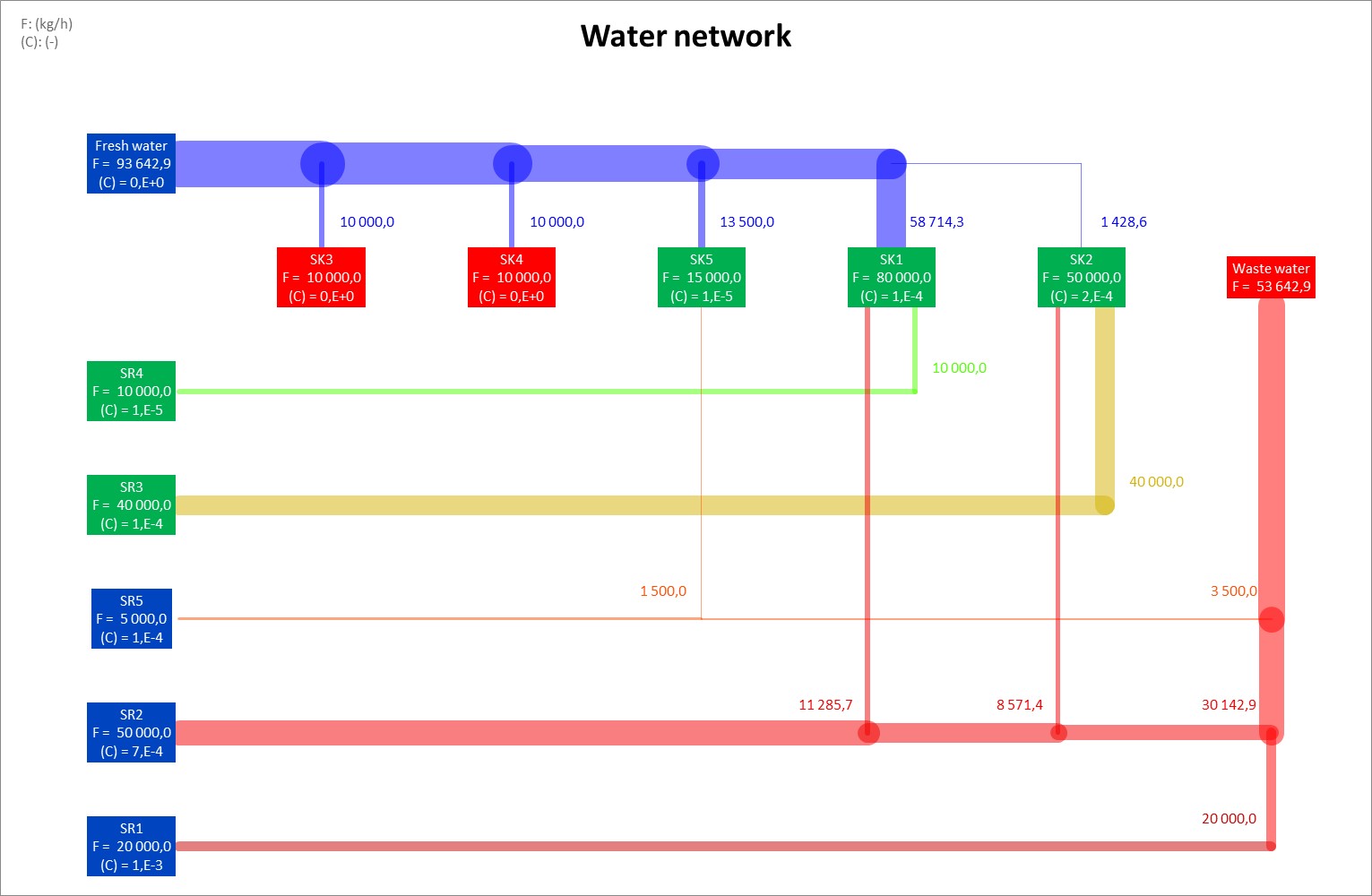

Simulis Pinch Water relies on the mass pinch method to find the most efficient reuse between the rejection and the water requirements of a process. The objective of this tool is to provide an efficient water network that limits rejection and reduces the water consumption of a process.

A tool dedicated to energy and water efficiency using the pinch method.

The first functionality provided by Simulis Pinch is to perform the audit of the process based on the Pinch technology using the characteristics of the streams in the process.

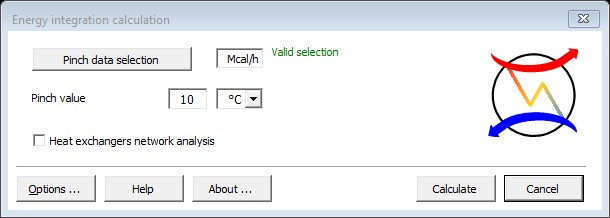

- For an energy diagnostic of the process, the hot and cold streams of the process (defined by their initial temperature, their final temperature and their energy flow) are used to identify the minimum requirements in hot and cold utilities and the maximum of energy that can be recovered by energy integration (for a pinch value chosen by the user).

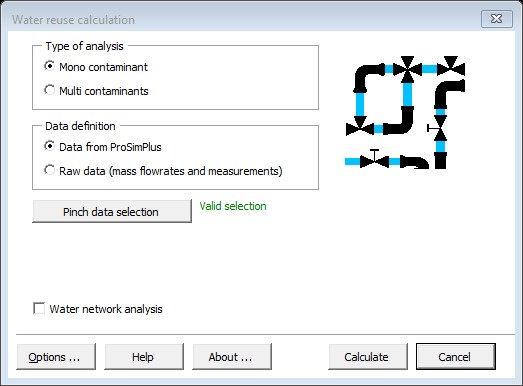

- For a water diagnosis, the process water requirements and rejection (mass flow and contaminant content) are used to determine the theoretical minimum of used and rejected water produced by the process, as well as the maximum of water theoretically reusable within the process.

Simulis Pinch provides all the needed information to estimate the potential savings available in the process. The diagnostic results can be viewed in different formats (composite and grand composite curves). This energy and/or water diagnosis makes it possible to determine the energy and environmental efficiency of the process by comparing the real consumption of the process with respect to the theoretical minimums.

Diagram TQ – This chart illustrates the need in hot utility, in cold utility, the maximum recoverable heat duty and the pinch temperature.

The area that applies to the recoverable heat duty appears in green.

Hardware requirements

Intel (or equivalent) based PC with:

- Computer (virtual or physical) running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Microsoft Excel™ 32 bits or 64 bits.

- Internet access: only to download the software and the license.

Simulis Pinch: process integration tool in Microsoft Excel™

- Simulis Pinch is an independent tool, directly available in Microsoft Excel™. It also can be used within ProSimPlus software. Then, the combination of ProSimPlus and Simulis Pinch identifies opportunities to reduce operating costs and increase throughput with an energy and water utilization analysis. This combination is very powerful when trying to improve the energy and water efficiency of complex processes.

- Simulis Pinch Energy’s pragmatic approach is to propose, in a very short time, various heat exchanger networks that meet the real constraints of the industrial site (fluids compatibility, couplings only within the process unit, distance, complexity…) during the design or revamping of a process. The various exchanges between hot streams and cold streams and the overall exchanger network generated by Simulis Pinch can be viewed in different formats: a grid diagram, composites curves, tables of numerical values…

The list of hot streams and cold streams flowing inside the process with their characteristics (initial temperature, final temperature and energy flow) can be entered in Excel or can be generated automatically during a process simulation using ProSimPlus.

- Simulis Pinch Water offers an automatic method of proposing a water network based on the selection of the most efficient reuse. This synthesis of the water network takes into account the constraints of the site (incompatibilities of fluids, couplings restricted to each site, distance, difficulty, etc.) and the criteria defined by the user (minimum reuse rate, percentage of reuse compared to the initial water resource). The design of the water network can be done from a single or multi-contaminant analysis.

- The various diagnostic results and the overall heat exchanger or water network can then be viewed in various graphical forms (temperature/enthalpy diagram…).

- The various exchanges between hot streams and cold streams and the overall exchanger network generated by Simulis Pinch can be viewed in different formats: a grid diagram, composites curves, tables of numerical values… In addition, a CAPEX study can be performed to revamp or retrofit the heat exchangers network

- In addition to being easy-to-use and user-friendly, since Simulis Pinch is used directly in Excel, the user can take advantage of all of the additional data and results processing available in Excel, and also combine Simulis Pinch with other Excel-compatible tools available from ProSim, such as Simulis Thermodynamics (mixture properties and fluid phase equilibria calculations solution) or Simulis Numerics (library of numerical tools, optimization …).

- Energy integration calculation

- Grid diagram

- Water reuse calculation

- Water network generated by Simulis Pinch showing possible water reuse

View the recorded Webinar ‘Run an energy diagnostic with Simulis Pinch’

Simulis Pinch is an add-in in Microsoft Excel™. The functionalities of Simulis Pinch are accessible in any Microsoft Excel ™ spreadsheet. Dedicated to process integration, Simulis Pinch allows any engineer to easily apply the pinch technology to find the best possible use of energy and water in industrial processes. Simulis Pinch makes it possible to find an optimum network (heat exchanger and/or water) that achieves the right compromise between investments and operating cost, to reach the target of energy or water consumption reduction.

In addition to its ease of use, having Simulis Pinch directly in Excel allows the user to perform any type of additional processing of data and results.