ProSim DAC

Dynamic adsorption column simulation

ProSim DAC is a dynamic simulation software for adsorption columns. Both adsorption and regeneration steps (TSA, PSA, VTSA…) can be modeled. ProSim DAC is a decision support tool to conduct in-depth analysis of solid-gas adsorption operations including refinery hydrogen purification, isotopic separation, VOC emission control, solvent recovery… The software is mainly used in nuclear, air treatment and hydrogen studies.

Main features

Easy simulation and cyclic process management

In-depth analysis of solid-gas adsorption operations

A property database containing more than 2,200 components

A full set of thermodynamic models

A full set of isotherm models

SOFTWARE FOR THE SIMULATION, OPTIMIZATION AND ANALYSIS OF INDUSTRIAL GAS ADSORPTION PROCESSES

ProSim DAC is a software developed by ProSim engineers for process engineers. The objective of the software is to enable process simulation and optimization for a large range of industrial gas adsorption processes such as cyclic processes (pressure-swing adsorption, temperature-swing adsorption…). The software will allow the selection of optimal adsorbents, the design of improved adsorption cycles, and the improvement of general plant operations. The user is able to quickly test process modifications and their performance.

ProSim DAC is a specific software based on our successful ProSimPlus product, so it uses the same graphical user interface and graphical capabilities as ProSimPlus.

Easy simulation and cyclic process management

Modeling capabilities for a wide variety of adsorbents (activated carbon, zeolites…)

Many different models are included (isotherm type, thermal working, mass transfer model…)

BENEFITS:

-

- Cost reduction

- Improved process understanding

- Improved process design

- Improved plant operations

- Safety studies (hot spots…)

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

CHARACTERISTICS:

- Time-dependent feed characteristics

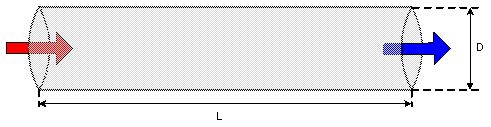

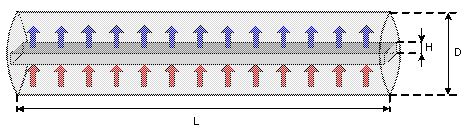

- Selection of 2 types of columns: lengthwise flow column or transverse flow column:

- Processes include Pressure Swing Adsorption (PSA), Temperature Swing Adsorption (TSA), Steam regeneration, Vacuum Thermal Swing Adsorption (VTSA)

- Database of properties for many activated carbon materials

- Isotherm library (Langmuir, Toth, Dubinin-Radushkevich, Langmuir extended, Sips…)

- Database and predictive isotherm for VOC – Activated carbon systems

- Cycle organizer and task manager

- Financial reporting

OBJECTIVES OF ProSim DAC:

- Dynamically simulate the operating conditions of the adsorption columns: adsorption and regeneration

- Solve the material and energy balance equations

- Calculate the properties of all fluids (flow, composition, temperature, pressure, properties…)

- Provide all the information needed to estimate the dimensions of industrial equipment (breakthrough time, adsorbed quantities…)