ProSimPlus HNO3

Simulation of nitric acid plants and nitrous vapors absorption

ProSimPlus HNO3 is a unique process engineering tool, specifically designed to model nitric acid production plants and nitrous vapors absorption units. It allows engineers to represent accurately and to analyse processes in which the absorption of nitrous vapours and associated complex physico chemical phenomenon intervene (nitrogen monoxide oxidation reactions, nitrogen dioxide dimerization reaction, nitrogen oxides absorption in nitric acid aqueous solutions…).

“The full set of equipment, the integrated thermodynamic, the ease of use and the ability to model many different design scenarios with ProSimPlus HNO3 allows me to study new plant configurations for the nitric acid industry. Also, working with the ProSim support team is like having a brilliant group of engineers on staff who respond quickly with appropriate solutions.”

“The full set of equipment, the integrated thermodynamic, the ease of use and the ability to model many different design scenarios with ProSimPlus HNO3 allows me to study new plant configurations for the nitric acid industry. Also, working with the ProSim support team is like having a brilliant group of engineers on staff who respond quickly with appropriate solutions.”

Jerry Davis, Nitric Acid Process Consultant (Kingwood, Texas, USA)

Main features

Industry specific equipment: absorption columns, nitrous vapors condensers, etc.

Many years of experience in properties calculations and in chemical reactions readily available

Complete mass and energy balances on the installation without time-consuming convergence tests

An easy-to-use graphical user interface for instant usability and fast learning

A reference software selected by leading actors in the field

ProSimPlus HNO3 is a process engineering tool specifically designed to model nitric acid production plants and nitrous vapors absorption units.

To face economic, environmental or safety challenges inherent to their activity, actors of the fertilizer industry, and nitric acid producers in particular, cannot be satisfied anymore with general simulation software. They need a reliable and efficient tool, capable of representing the full complexity of their production process.

To face economic, environmental or safety challenges inherent to their activity, actors of the fertilizer industry, and nitric acid producers in particular, cannot be satisfied anymore with general simulation software. They need a reliable and efficient tool, capable of representing the full complexity of their production process.

The software is used in design phases as well as in plant operations for process optimization, unit debottlenecking or plant revamping.

Thanks to a reliable modeling of the steady-state behavior of the installation, it helps to generate significant improvements in efficiency and profitability as well as to increase reactivity when facing new regulations.

Why HNO3 ?

The complexity of the physical and chemical phenomena involved in nitric acid processes (chemical reactions in gas phase in nearly all the equipment pieces, thermodynamic properties not easy to model,…) and the specificity of the equipment used in these units make the simulation of these processes nearly impossible with a general purpose simulation software. Typically, sizing parameters (pipes volume, absorption column trays spacing…) must be taken into account at early stages of process design as, when adding oxidation volumes, they affect the mass and energy balances.

This is generally not the case in other processes and these parameters are therefore not taken into account in standard simulation software. Some operating or engineering companies have developed specific in-house programs for the main unit operations but, beside usual maintenance and permanence issues, they often lack in flexibility and efficiency when looking at a complete process.

ProSimPlus HNO3 is built on over 30 years of experience in the modeling of nitric acid plants and nitrous vapors absorption units (thesis of Prof. Xavier Joulia – 1981 “Contribution au développement d’un programme général de simulation – Application à l’analyse du fonctionnement d’un atelier de production d’acide nitrique”). Since then, this know-how has constantly been enriched, updated and validated.

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

Represent your processes accurately

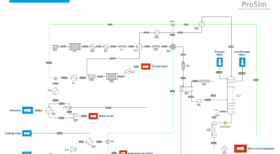

In addition to the unit operation library usually available in general simulation packages, ProSimPlus HNO3 offers a full set of specific equipment used in nitric acid production processes, in particular:

- Absorption columns for nitrous vapors by aqueous nitric acid solutions: chemical reactions in gas phase, mass transfer with chemical reaction in liquid phase, plate or packing towers, spray columns, plate coolers, etc.

- Nitrous vapors condensers using rate-based approach or simplified model.

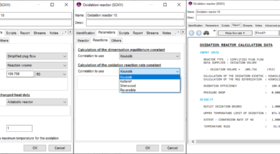

- Chemical reactors (or oxidation volumes): plug flow or CSTR, adiabatic, isothermal or specified output temperature, etc.

- Nitrous vapors compressors: one-stage or multi-stage, isentropic or polytropic efficiency, with the ability to provide manufacturers curves, etc.

- Heat exchangers, with possibility to take into account oxidation reactions in gas phase.

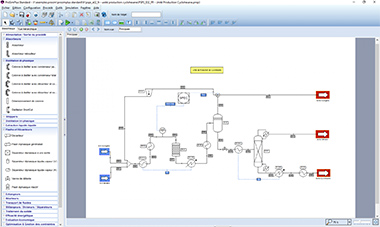

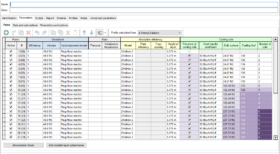

Interface ProSimPlus HNO3

Pinch analysis features are included (extraction of selected stream data, composite curves…) as well as the ability to run case studies to automatically perform sensitivity analysis.

ProSimPlus HNO3 is a particularly open software in which the user can integrate his own models and specific know-how.

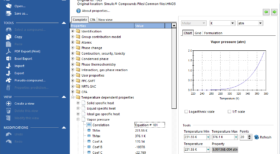

A vast know-how in properties and chemical reactions already integrated

The quality of a simulation rests above all on a good thermodynamic and chemical modeling of the system. ProSimPlus HNO3 includes physical and chemical models built on many years of research and validated by intensive industrial use. As these elements are readily available in the software, the user can concentrate on other aspects of his process. Among these elements one will find in particular:

- A complete properties database of the components involved in these types of process (H2O, NO, NO2, N2O4, N2, O2, HNO3, NH3, N2O, N2O3, HNO2, CO2, CO, CH4, H2, SO2, SO3).

- A thermodynamic model based on equations obtained from experimental measurements and able to accurately represent the non-ideality of the liquid phase (liquid fugacity, excess enthalpy, solution density…).

- A model particularly well suited to strong nitric acid concentrations (concentration or bleaching columns).

- Mass transfer with chemical reactions in liquid phase automatically taken into account: N2O4 and N2O3 absorption, HNO3 and HNO2 hydrolysis or HNO2 decomposition.

- Chemical reactions in gas phase automatically taken into account, with specific correlations:

– NO to NO2 oxidation reaction kinetic model in gas phase: Sherwood’s, Koukolik and Marek…

– NO2 to N2O4 dimerisation equilibrium constant in gas phase: Koukolik and Marek, Bodenstein…

– N2O3 formation equilibrium constant in gas phase: Miller, Beattie and Bell…

– NOx-H2O-HNO3 systems equilibrium constant: Koukolik and Marek, Zhidkov, Carberry…

Unrivalled convergence methods for immediate results

Specifically adjusted algorithms, based on the simultaneous modular approach, are particularly well adapted to the complexity of these processes. This development, unique in the world of simulators, comprises in particular:

- Automatic determination of the calculation sequence: stream initialization and tear streams are not required;

- Simultaneous treatment of recycling and design specifications through proven methods;

- Multivariable control approach that allows imposing one or several process outputs by simultaneously adjusting one or several selected parameters;

- The possibility to simulate the process partially after a parameter modification, instead of running the full simulation over again.

- At each unit operation level, a fast and reliable convergence is ensured by using the method best suited to the equation system to be solved and a generalized use of analytical derivatives.

The industry reference software, quickly adopted by users

World leading engineering firms in the nitric acid field and most efficient fertilizers producers already rely on ProSimPlus HNO3 to design new units or revamp existing plants.

This software is also extensively used in industries dealing with NOx: energy, chemical, nuclear, etc.

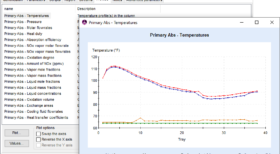

ProSimPlus HNO3 is very intuitive. The MS Windows® based graphical environment provides many features to easily built process flow diagrams: drag and drop, copy and paste of unit operations, colors, sizing, sub-flowsheets, tree view, images and text insertions, zoom facility, different views of the same process… and to quickly analyze and understand simulation results (charts plotting, global material balances calculation directly from the flowsheet, NOx content, oxidation degree…). During and after the simulation, convergence status is shown on the diagram and in the simulation report (along with indications on the source of error). The complete report is generated in HTML and MS-Excel formats and flowsheets and charts can be copied and pasted in other environments or saved in .BMP or .EMF formats.

- Interface

- Compound properties

- Oxidation reactor

- Plate oxido absorption column configuration

- Graphic display of stream data

- Plate oxido absorption column profile

Applications

For instance, ProSimPlus HNO3 is very well adapted to simulate the production of synthetic fertilizer, to optimize the fertilizer production or manufacturing processes… Other uses include the production of explosives, the etching and dissolution of metals and in organic oxidation in adipic acid manufacture.